Our Process

1. Surface preparation

If required, we prepare the metal surface by sandblasting, sanding or both.

2. Acid bath

Aluminium products are dipped in an acid based immersion cleaner and chromate conversion coating to remove impurities and improve adhesion.

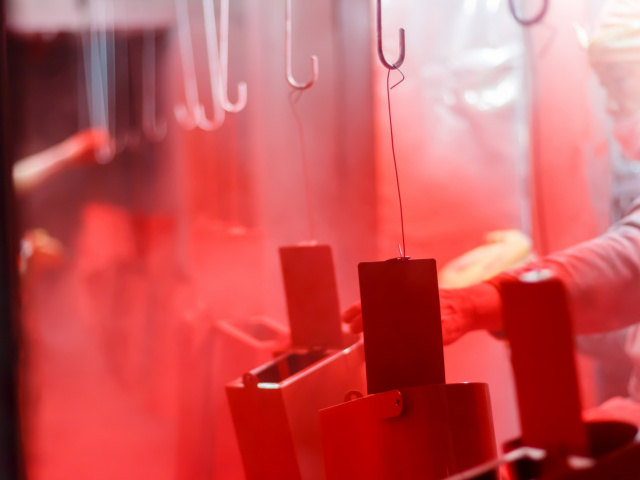

3. Powder coating

The product is then electrostatically coated in colour powder.

4. Curing

The colour powder is then cured onto the product by firing in our large powder coating oven at approx. 200°c.